Open Source Velomobile Development Project

Sommaire |

Project Objectives

To collaboratively develop methods for velomobile construction.(What is a velomobile?)

Cost: Getting the cost under $2500 for a basic model with little owner building. $7k and a round trip to Europe is too expensive. But $7k for a fully decked out one bought locally with local service might be OK for more people, hopefully.

Ability to obtain: One curently researches and partially builds a VM, or goes to Europe and brings one home, or hopefully one can buy one in Texas very soon. Making VM's easier to find , to watch, to test, to dabble in, to build, to buy; All of this is needed to increase the number of VM's on the road.

Ability to use:

Fairings make the vehicle heavier and bigger, sometimes limiting the use, but is somewhat offset by the fairing's weather protection and road riding space allocated by other vehicles. Utilizing electric assist will enable many more users that are not extremely physically fit, also senior citizens and partially handicapped people.

Social Implications

The Velomobile as a Vehicle for more Sustainable Transportation Reshaping the social construction of cycling technology - by Frederik Van De Walle (PDF file)

Stereotyping; By increasing the numbers of velomobiles on the road we dispell that notion that they are expensive toys ridden by eccentrics and kooks. When they can be test ridden and no longer are some distant mysterious contraption invented for just european use, when the use can be logically analyed, the stereotype will melt away.

Dick

Open Source Velomobiles - evolution or revolution?

a few thoughtful insights in the group building,intricacies,and economics of such a project on the German site http://www.velomobile.de/

Process of Collaboration

Post your work here to share with others. Collectively we will be able to achieve much more than individually.

This is a wiki; that means you can edit any page or page section. If you want to contribute or if you see something that needs fixing, go for it! For more on editting, see this wikipedia entry.

See also Creative Commons: Attribution-ShareAlike 2.0 regarding sharing of content. (Or help out the PedalWiki by adding some content to the [Pedalwiki:Copyrights] page)

Design and Materials

Simulation and modelling

http://www.x-plane.com/ (simulation program (free trial / $50)

http://www.x-plane.org/registry/5666.shtml (motorcycle simulator module)

http://sketchup.google.com/ (Google SketchUp)

Add-ons for existing trikes

Body

Potential skin materials planned to be used: Coroplast, Zotefoam, other plastic/ ABS?, etc. Frame support material?

Temperature/ color issues?

accommodations for ventilation? heal strike openings? Knee height at what distance? external mounts for customer installable lights and possible windshield? maintains shape to 45 mph?

The bodywork of the Versatile is formed from TwinTex.

Example of body design with airscoop and recesed cavity for front lighting. Mirror bumps can be added easily:

http://www.design4today.com/temp/velo-faring-design4today-01.jpg

Here is a similar body for a delta (two wheels in back) trike, in this case, the EZ3 by Sun Bicycles

http://www.design4today.com/temp/velo-faring-design4today-02.jpg

Stitch and Glue hull building method: The folks at Pygmy Boats have a great set of products for kayak construction in the form of kits, and have a great set of step by step illustrations on their website for this lightweight technique: http://www.pygmyboats.com/Construction.htm

FreeShip software: FreeShip is a sub-division surface modeling software that is designed to aid in hull design and construction and has some exciting features such as automatic checking for "Fairness", adding or removing hard creases or "chines" and even a test to determine if a model can be built from single curved survaces such as plywood (or coroplast for us). Another nice feature will let you "flatten" your hull or faring in order to cut the pieces. http://www.freeship.org/

Autodesk VIZ and/or Autodesk 3ds max, www-autodesk-dot-com. If you are a student you can get great discounts on educational licenses for these products...try www-studica-dot-com The software is a difficult to learn but there are many tutorials available on the web. You might find a local community college that teaches a class using the software as well. Viz and max import and export Autodesk .dwg format, so getting your models into AutoCAD for shop drawings should not be a problem.

Chassis

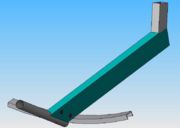

Greg Nuspel's frame ideaThe concept is to have a frame that can be put together using standard hand tools. Using standard aluminum extrusion sizes I quickly drew up the image. The cross member can be bent by most welding shops set up for tubing bending. The rectangular main tube makes it easy to mount seats etc. The tube extending out to the bottom bracket is held on by bolts threaded through the round bars going through the main frame member. I know this would not be the lightest frame design but lightning holes could be cut through the main tube. Parts can be fastened on using rivnuts.

Metal-Aluminium frame : for efficiency and torsion resistance : is it necessary with self carrying fiber chassis ? Would fiber only resist torsion efforts while cycling ? Yves Bertin

Leif Steinhour adds: We've had some very good success with using wood to build bike frames from (lots of other people on the net have also). My link below details our efforts, but since the density of wood is so much less than steel, you can go very large with your tubes without running into the sort of "tin can" structural issues that you get with making very large but very thin walled tubes out of steel or aluminum. What's also nice about this is that it does not require anything more fancy than a drill press and a good spade bit to make a complete frame with (assuming you purchase steel bottom bracket and headset shells).

I'm also planning to use a lot of wood and bamboo, with some fiberglass to make secure joining easy. An epoxy coating on everything keeps it light and dimensionally stable. Wood has excellent fatigue properties, and is well suited to a frame with integrated suspension. A bit of 'glass reinforcing makes it much more versatile if clearance isues arise. In general, things like bamboo and unidirectional carbon-fiber tubes will need a wrapping of synthetic fiber at about 45 deg to the main axis to resist torsion.

A monocoque construction as proposed by Yves can be done with just small metal inserts for mounting points, and it can give more protection in a crash, but in our size/load regieme it is always heavier than a well-engineered backbone frame with a flexible shell, unless it is made so thin that it is very expensive and fragile. It works better with exposed wheels, but that is an aero liability.

On the drawing shown, see that the bottom of the front crossmember is very highly stressed, in fatigue-prone aluminum, and the C section does not provide the necessary torsinal resistance to mount brakes. Requires some calculations from dimensioned sketches.

Electrical assistance

Power choice between 100-250W to stay reasonable.

12V+ systems can be effective if motors are chosen carefully. The readily available discontinued Go Motorboards 1500X mini-scooter has dual 350watt motors with a 12V battery pack. The motors are specially-designed high-torque low-rev models and the shafts directly drive the sides of the wheel by friction.

One example of hubdrive http://www.extraenergy.org/main.php?language=en&category=products&subcateg=&id=805 With four assist and four regen modes, BionX is a pedelec system and a training tool. Canadian manufacturer EPS is preparing to sell the compact hub drive unit also in Europe. The 250 Watt hub motor including power sensor and electronics comes in a ready-to-use rear wheel. The 8 Ah, 34 V NiMH battery is located in a compact battery box. To mount the system to any regular bicycle one only needs to exchange the rear wheel. The entire system weights 6.6 kg. The motor, controller, cables and display weigh 2.5 kg, and the battery 4.1 kg... www.bionx.ca

http://www.extraenergy.org/main.php?language=en&category=&subcateg=&id=824 BatteryTest: Five more Li-Ion Batteries The new year has started off with 12 test participants total and a new generation battery boxes are lighter, stronger and cheaper in production... In January, five new participants have signed up for the test. The Chinese Lithium-Ion battery manufacturers are customers of Degussa, the World's largest maker of specialized chemistries. Improved Battery Boxes The first 30 new generation battery boxes have arrived. They are made of glass fibre composite material and are stronger, cheaper in production and lighter in weight. With the electronics included, one box weighs only 1.5 kg (3.3 lbs) which allows a maximum battery weight of 6 kg (13.2 lbs).

Velomobile Humour (reality?)

Ten Ways To Reduce The Speed of a Velomobile - by Reg Rodero, 2006

1. Replace the smallish youthful well trained engine with a larger aging slightly overweight (minor health issues) engine.

2. Make the body larger than a typical streamliner to improve comfort and increase frontal area.

3. Add a third wheel to improve stability at low speeds. If you put the wheels the wrong way around it will still work.

4. Cut some holes in the body to give adequate ventilation and upset laminar flow. Opening windows. doors vents.

5. Add suspension to reduce the noise level, improve the ride and add more weight.

6. Give up the high speed gearing in favor of some nice low gears that will allow you to get up a hill without your legs burning. Now that you have the third wheel you can use some very low gears and not fall over.

7. Forget to oil your chain.

8. Let some air out of your tires or just ignore them and they will do it automatically.

9. Add some spare parts tools and large heavy containers of your favorite beverage. Fire wood a baby seat. Use your imagination.

10. Get rid of those small rear view mirrors that just pass tech inspection and replace them with larger ones that you can actually see that tractor trailer bearing down on you.

Well that is ten. There are more if you wish to share. I apologize to anyone I may have offended. I feel better now.

Reg Rodaro, 2006

Sample Velomobile Links

The North American Velomobilist Website Created by Ethan Davis

Flevobike Technologies Home of the Versatile velomobile

Dutch Speed Bicycles Home of the KV4 velomobile

Velomobiel.nl Home of the Quest and the Mango velomobiles

Aerorider Electric assist velomobile

Kunststofftechnik Beyß Home of the Go One

Hypertrike Project Open Source Conversion for tadpole trikes to velomobiles

Association pour le développement des vélomobiles : French news about velomobiles, history, links..

Bries Ideas about a developable surface (Bratmobile) and a modular zotefoam-and-tube fairing.

Rotator Coyote - Designed and constructed by Steve Delaire and Dean Pederson

Alexian Steerer - Designed and constructed by Leif Steinhour. This link also details a new method of fairing construction using sheet stock and pipe glue.

Fotoboek Thomas van Schaik Here's a posting from the ligfiets list on a home-built VM that is mounted on a trike frame. If you look down through the page that the link refers to, you'll find four links to photos of the Zelfbouw (Home-Built) project in various stages. (posted to velo list)

Last but not least (maybe not last either; these things do keep trickling in): http://fotos.ligfiets.net/oliebollentocht-2004/index.html has a set of 90 pictures of the Oliebollentocht, including a large number of group scenes, and some of velomobiles riding below a rainbow. Andr� Vrielink of Flevobike (manufacturer of the Versatile) is the source for these nice photos. (posted to velo list)

Watch the building of a flat pack velomobile kit Building project started October 25, 2006. In French, but with loads of pictures

Arcturus Human Hybrid RV - This Velomobile will sleep two adults and have as much interior room as a truck camper. This is my work log as the build progresses.

Building Resources

Gaerlan Custom Cycles Bike parts for home builders

Aircraft Spruce Good source for materials, especially steel and aluminum tubing.

IHPVA pages: Builder's Corner old articles and links to builder's pages. The Source Guide is also desparately in need of updates; it will be migrated to a member supported site like this one "real soon".

WISIL pages: HPVers Project Page (research and development)

Recumbent parts for homebuilders Even a flat pack velomobile kit (although not to the USA, for liability reasons)

Technical Information

[http://www.rqriley.com/3-wheel.htm Three Wheel Cars - Primary Factors That Determine Handling & Rollover Characteristics] by Robert Q. Riley

THE CAR-CYCLE X-4, a PIONEER of INTEGRATED SUSPENSION By Robert K. Stuart

Zote Foam fairing - building techniques by John Tetz

Speed101 Explore Concepts of Speed - Matt Weaver

Human Power eJournal - Several relevant articles in the first issue

Human Power archive - The online archive of the IHPVA "Journal of Human Power", issues 1-55

"The Dynamic Stability of a Fully Faired Single Track Human Powered Vehicle" - Doctoral dissertation of Gregory K. Watkins, PE

Velomobile seminar proceedings order page : go to Literatur / Shop

Velomobile and seminars in English Dutch and German

Participants

(Note that if you put your wiki account name here, other wiki users have a way to contact you.)

Juergen Weichert, Matt Thyer*, Elrey*, Jim Robb(jimrobb)[1], Dick in Colorado, Brian Wilson - Oregon (Destiny), Yves Bertin - France, Trev Holland - Western Australia (trev) Brad Graham - Thunder Bay, Ontario, Canada [2], Tim Taylor - Utah, USA (ttaylor07) Theo Schmidt - Switzerland